Notice: Undefined variable: kategorija_naslov in /home/johnroe/public_html/product_detailed.php on line 105

Notice: Undefined variable: page_title in /home/johnroe/public_html/product_detailed.php on line 188

Notice: Undefined variable: page_short in /home/johnroe/public_html/product_detailed.php on line 196

GEOTUB® ist a modular formwork in ABS plastic material, resistant to UV and chemical agents.

The forms are very light and can be handled manually and installed by a single person. The product can be reused more than 100 times.

The internal smoothness of the formwork and the quality of the material guarantee a pleasant look and allow an easy installation and dismantling without any releasing agent. After the pour, remove any external deposit of concrete and clean the product with water.

The single forming elements are quickly and easily joined using the standard high-strength nylon fastening handles.

A - GEOTUB

B - HANDLE

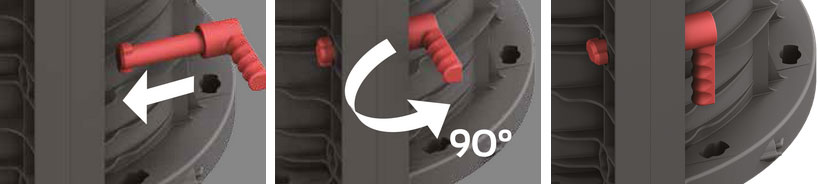

HANDLE ASSEMBLY

For a quick and correct installation of Geotub® formwork, please follow these steps: All fixing handles must be fastened to ensure the specified strength of the formwork. The rotation direction of the handles does not affect their strenght.

|

|

|

||

1. |

2. |

3. |

||

| Juxtapose two semi-circular Geotub® parts; | Insert the high-strength nylon fixing handles from the bottom of the form up. Turn each handle by 90° to lock the parts; | The last handles at each end of the part junction flange are turned by 90° inwards; | ||

|

|

|

||

4. |

5. |

6. |

||

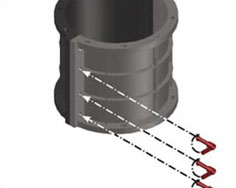

| The locking of the handles is easier if these are inserted alternately from the two sides of the form joining flange; | The handle grip is indifferently oriented upward or downward, preferably without overlapping any two of them. (fig. 5 shows the ideal handle position). Continue coupling the Geotub® modular elements, interlocking them vertically and horizontally, until the desired formwork height has been reached. The full locking of all the handles guarantees the specified strength of the formwork and furthermore ensures the correct alignment of every part of the formwork; | Once the Geotub® column formwork is assembled, fix it to the ground with wooden reinforcements; | ||

|

|

|||

7. |

8. |

|||

| The plumbing of Geotub® is easy and fast: two standard props are enough to stabilise the form. | RESULT AFTER POUR AND DISMANTLING. |

REUSE

INSTALLATION ADN DISMANTLING

MODULARITY

STORAGE

ON-SITE HANDLING

RESULT

| ARTICLE | GEOTUB® | SONOTUBE | PILASTRI RS | SRS |

| MATERIAL | ABS | CARDBOARD | STEEL | STEEL |

| MAX DIAMETER COLUMN (cm) | ø100 | ø150 | ø60 | ø70 |

| MAX WEIGHT PANEL (kg) | 4 | N/A | 217 | 217 |

| MAX PRESSURE RESISTANCE (KN/m2) | 150 | N/A | 150 | 150 |

| RELEASING AGENT | NO | NO | YES | YES |

| HANDLING | MANUALLY | MANUALLY | CRANE | CRANE |

| INSTALLATION TIME (min/colonna) | 15 | N/A | N/A | N/A |

GEOTUB is a formwork made of ABS plastic material, resistant to UV and chemical agents.

| GEOTUB | ø 25 cm | ø 30 cm | ø 35 cm | ø 40 cm | ø 45 cm | ø 50 cm | ø 60 cm | ø 70 cm | ø 80 cm | ø 90 cm | ø 100 cm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MATERIAL | ABS | ||||||||||

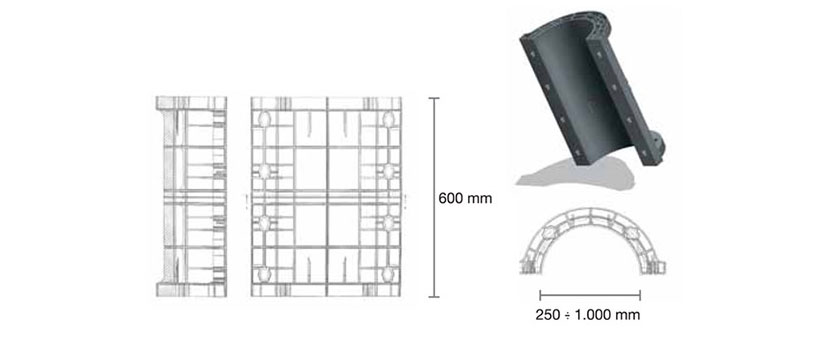

| Internal diameter | 250 mm | 300 mm | 350 mm | 400 mm | 450 mm | 500 mm | 600 mm | 700 mm | 800 mm | 900 mm | 1000 mm |

| Single form length | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Maximum column length | 6 m | 6 m | 4,8 m | 4,8 m | 4,8 m | 3 m | 3 m | 3 m | 3 m | 3 m | 3 m |

| Package dim.(cm) | pallets dim. 81x121x h220 |

pallets dim. 81x121x h245 |

pallets dim. 104x121x h225 |

pallets dim. 114x121x h192 |

pallets dim. 121x123x h235 |

pallets dim. 80x121x h211 |

pallets dim. 80x121x h236 |

pallets dim. 87x121x h235 |

pallets dim. 100x121x h227 |

pallets dim. 100x121x h243 |

pallets dim. 120x121x h231 |

| Nr. pieces per pallet | 60 | 60 | 50 | 40 | 48 | 20 | 20 | 18 | 16 | 16 | 14 |

Notice: ob_end_flush(): failed to delete and flush buffer. No buffer to delete or flush in /home/johnroe/public_html/inc/footer.php on line 217